Dhokla Machine for Smart Production

Commercial Dhokla Making Machines are designed for uniform quality, high capacity and long-lasting performance for your food business.

Dhokla looks simple on a plate. Soft. Spongy. Light. In production, it is anything but simple. Anyone who has tried making dhokla in large quantities knows where things start slipping. One tray rises well. Another does not. Steam distribution changes. Batter behaves differently by afternoon. Texture varies just enough for customers to notice.

This is where a Dhokla Machine becomes relevant, not as a luxury, but as a stabilising tool.

In India, bulk dhokla production has moved far beyond hand operated steamers. Restaurants, caterers, cloud kitchens, and packaged food manufacturers now depend on machines to maintain consistency, hygiene, and output. The shift is not about speed alone. It is about control.

What Is a Dhokla Machine?

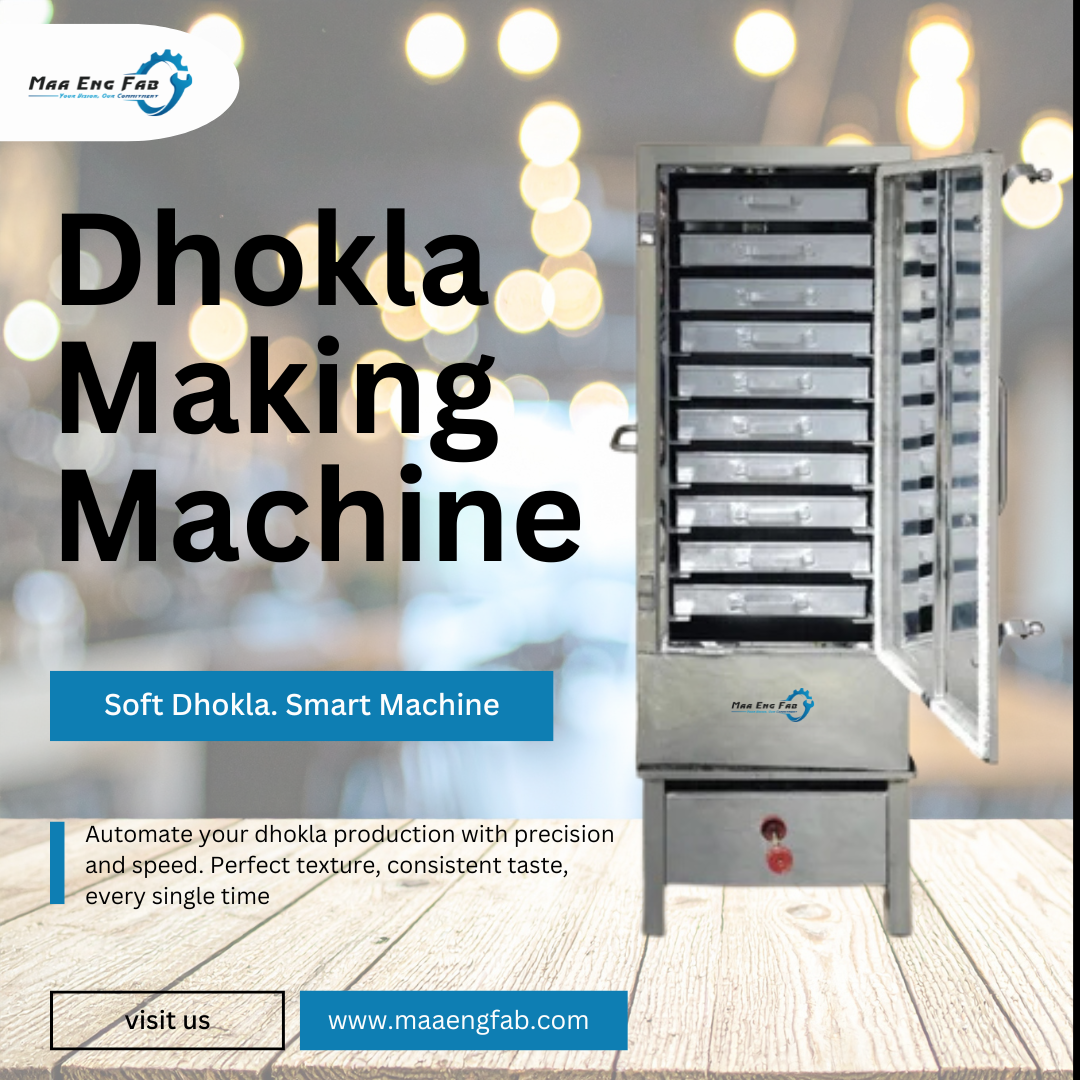

A Dhokla Machine is a commercial food processing machine designed to steam dhokla batter under controlled conditions. Unlike traditional setups that rely heavily on experience and manual judgment, the machine standardises heat, steam flow, and cooking time.

Most machines are built using food grade stainless steel, commonly SS 304, to meet hygiene requirements and withstand continuous operation. The design typically includes a closed steam chamber, tray holding systems, and controlled steam input.

Some machines handle only the steaming process. Others are part of a larger system that includes batter handling and post cooking discharge. The configuration depends on production scale, not preference.

Why Manual Methods Fail at Scale?

At small volumes, manual dhokla preparation works. At scale, it starts breaking down.

Steam distribution becomes uneven. Trays placed closer to the steam source cook differently from those at the edges. Timing errors increase. Operators compensate instinctively, but instinct does not scale.

This inconsistency affects texture, moisture retention, and shelf stability. For businesses supplying hundreds or thousands of plates a day, variation quickly turns into waste.

A Dhokla Machine removes much of this variability by fixing the parameters that matter. Temperature remains steady. Steam circulates evenly. Cooking cycles are repeatable.

That repeatability is the real value.

Types of Dhokla Making Machines Used in India

Not all dhokla machines are built for the same purpose. Indian food businesses operate at very different scales.

Small farsan shops and restaurants often use compact or semi automatic dhokla making machines. These are tray based steamers designed to improve efficiency without full automation.

Catering units and cloud kitchens typically move to batch type machines with larger chambers and higher tray capacity. These allow multiple batches to be processed with consistent results.

Large dhokla manufacturers producing packaged dhokla products rely on fully automatic or continuous dhokla machines. These systems are designed for uninterrupted production and can be linked to cooling, cutting, and packaging lines.

Choosing the wrong type usually leads to either underutilisation or operational bottlenecks.

How a Dhokla Machine Actually Works?

The working principle of a dhokla making machine is based on controlled steam cooking, but execution matters.

Prepared batter is poured into trays or moulds and loaded into a sealed chamber. Steam is generated either by an inbuilt boiler or supplied from an external source. Once the chamber reaches the required temperature and pressure, steam circulates evenly across all trays.

Cooking time is fixed. Not estimated. Not adjusted mid cycle.

At the end of the cycle, trays are removed or discharged depending on machine design. The result is dhokla with uniform height, softness, and internal structure.

This process sounds straightforward. In practice, achieving stable steam circulation is where machine quality shows.

Why Uniform Steam Matters More Than Heat?

Many assume higher heat cooks faster. With dhokla, that logic fails.

Excessive heat dries the surface before the centre sets. Insufficient heat leaves the core undercooked. Steam must penetrate evenly, not aggressively.

A Dhokla Machine focuses on distribution, not intensity. The goal is even expansion of batter across trays, not speed.

Operators who shift from manual steaming often notice this difference immediately. Texture becomes predictable. Rejections drop.

Advantages of Using a Dhokla Machine

The benefits of using a dhokla making machine are operational, not theoretical.

- Production output increases without increasing labour proportionally

- Batch to batch consistency improves significantly

- Hygiene levels rise due to closed steam chambers

- Cooking time becomes predictable

- Dependence on highly skilled manual supervision reduces

These advantages matter most in commercial kitchens where time, cost, and repeatability decide profitability.

Role of Dhokla Machines in Packaged Food Manufacturing

Packaged dhokla production introduces another layer of complexity. Shelf life, moisture control, and uniform size become critical.

Manual variation, acceptable in fresh service, becomes a liability in packaged formats. A Dhokla Machine allows manufacturers to lock in cooking parameters and repeat them across large volumes.

Machines are often integrated into production lines where dhokla moves from steaming to cooling, cutting, and packing without unnecessary handling. This reduces contamination risk and improves throughput.

In India, this approach supports the growing market for ready to eat and ready to steam dhokla products.

Factors That Influence Dhokla Machine Price

The dhokla machine price in India is not fixed. It varies based on technical and operational factors.

Key influences include:

- Production capacity and batch size

- Level of automation and control systems

- Material grade and finish quality

- Steam generation method

- Customisation requirements

A small semi automatic dhokla making machine and a continuous industrial system may serve the same product, but their pricing reflects entirely different use cases.

Understanding Dhokla Machine Price Ranges

Entry level machines designed for limited daily output fall into lower price brackets and suit small businesses.

Mid range machines serve restaurants, caterers, and cloud kitchens with moderate volume requirements.

High end systems designed for industrial production carry the highest dhokla machine price, justified by automation, integration capability, and long duty cycles.

Comparing prices without considering capacity often leads to poor decisions.

Maintenance and Daily Operation Reality

A Dhokla Machine is not maintenance free, but it is predictable.

Steam chambers need daily cleaning. Trays must be washed thoroughly. Gaskets and valves require periodic inspection. Machines designed with easy access panels reduce downtime.

Neglecting routine maintenance usually shows up as uneven cooking, not immediate failure. This makes discipline important.

Food Safety and Compliance in India

Commercial dhokla production must comply with food safety norms.

Most machines used in India are designed to meet FSSAI expectations, focusing on food grade materials, smooth surfaces, and cleanability.

Using compliant equipment simplifies audits and reduces operational risk.

Contact Dhokla Making Machine Manufacturer

The Dhokla Machine has become a practical necessity for bulk dhokla production in India. It brings consistency to a process that struggles with scale when done manually.

Understanding how the machine works, where it fits in production, and how dhokla machine price relates to capacity helps businesses choose equipment realistically.

As traditional foods continue moving into commercial formats, dhokla making machines will remain central to balancing authenticity with efficiency.

You can contact best dhokla making machine manufacturer like, Maa Eng Fab to get best equipment as per your business requirement.